There are four kinds of conformal coating (conformal adhesive) use process: brushing, dipping, spraying, and spraying. Let's take a look at what to pay attention to in different processes with Beginor Material!

Conformal coating method

The coating method is a less commonly used conformal coating method.

The conformal coating, which is stored in a high tank, is poured down through a nozzle or narrow slit and drenched on the coated object driven by the conveyor in the form of a curtain to form a uniform coating film. The excess conformal coating flows back into the container and is pumped into a high-level tank for recycling.

In small batch production, manual operation is generally used to directly pour conformal paint on the product, so the spraying method is also called the paint pouring method.

In large-scale production, automatic assembly line operation is generally adopted, and the thickness of the conformal coating film on the product is controlled by adjusting the size of the nozzle or the width of the narrow slit. If the coating film is thick, bubbles will appear on the coating film on the product that comes out of the conveyor belt through the drying box. If the coating film is thin, the product will appear exposed and unevenly coated. Therefore, the coating method is also called curtain coating.

According to the characteristics of different products, in order to increase the adhesion of the conformal coating film on the product, it is sometimes necessary to add sulfurization, and in order to increase the thickness of the product, it is necessary to coat and sulfurize the product once or several times.

The conformal coating, which is stored in a high tank, is poured down through a nozzle or narrow slit and drenched on the coated object driven by the conveyor in the form of a curtain to form a uniform coating film. The excess conformal coating flows back into the container and is pumped into a high-level tank for recycling.

In small batch production, manual operation is generally used to directly pour conformal paint on the product, so the spraying method is also called the paint pouring method.

In large-scale production, automatic assembly line operation is generally adopted, and the thickness of the conformal coating film on the product is controlled by adjusting the size of the nozzle or the width of the narrow slit. If the coating film is thick, bubbles will appear on the coating film on the product that comes out of the conveyor belt through the drying box. If the coating film is thin, the product will appear exposed and unevenly coated. Therefore, the coating method is also called curtain coating.

Reminder: According to the characteristics of different products and the requirements of the spraying object, in order to increase the adhesion of the conformal coating film on the product, sometimes it is necessary to carry out vulcanization, and in order to increase the thickness of the product, it is necessary to coat and vulcanize the circuit board once or several times

Conformal coating spraying method

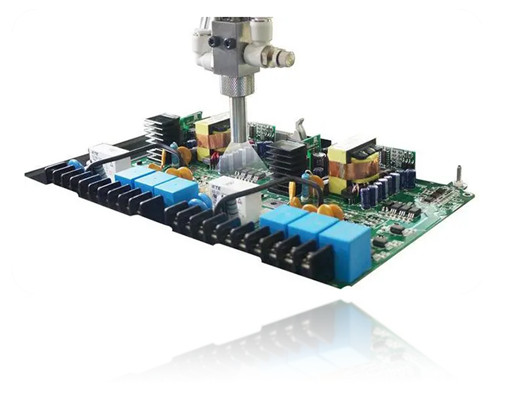

The spraying method is the most commonly used coating method in the industry, and it is divided into two types: automatic spraying by machine and manual spraying.

Among them, machine automatic spraying is suitable for customers with large-scale production, large quantities or long-term production.

Advantages: selective spraying, high accuracy, uniformity, high efficiency, and automatic detection.

Disadvantages: high cost, high requirements for operation accuracy, and possible shadows (where the lower part of the component is not covered with conformal coating).

And manual spraying is generally a combination of hand-held spray gun + air pipe + air compressor (+ exhaust fan). The advantages are: low cost, suitable for medium-sized customers. But it requires more than 5KG pressure to form a fog barrier, so the adjustment of air pressure is required to be higher, if the air pressure is not high, the conformal paint is not atomized, it will be drawn, and the accuracy of manual spraying is also relatively high.

Hand can spraying is also a kind of manual spraying, using spray can type products, suitable for maintenance and small-scale production, the biggest advantage is convenience.

In short, the investment of manual spraying is small, the operation is simple, the coating consistency of machine automatic spraying is good, the production efficiency is the highest, it is easy to realize online automatic production, and it can be suitable for large and medium mass production. Consistency and material cost are generally better than dip coating, and although a masking process is required, it is not as demanding as dip coating.

The corresponding disadvantages are: the need for masking process, large waste of materials, the need for a lot of manpower, poor coating consistency, may have a masking effect, and enter the difficult dimension under the narrow spacing components

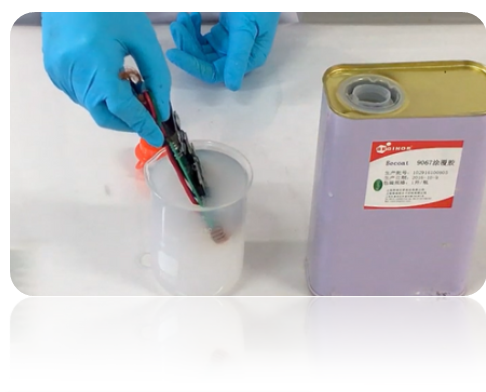

Conformal paint dipping method

Dip coating has been widely used since the beginning of the coating process, and is suitable for occasions that require complete coating, and the dip coating method is one of the most effective methods in terms of coating effect.

Advantages of dip coating: It can be applied manually or automatically. Among them, it is easy to operate by hand and has a low investment, a high material transfer rate that can completely coat the entire product without masking effect, and an automated dip coating equipment that can meet the needs of high-volume production.

Disadvantages of dipping coating: if the coating material container is open, with the increase of the number of coatings, there will be impurity problems, the material needs to be replaced regularly and the container is cleaned, and the same solvent volatilization also needs to be continuously replenished; the coating thickness is too large and a lot of material will be wasted due to dripping after extracting the circuit board; the corresponding parts need to be covered; covering/removing the covering requires a lot of manpower and material resources; the coating quality is difficult to control. Poor inversion: too much manual handling may cause unnecessary physical damage to the product.

The main points of the dipping method: the loss of solvent should be monitored at all times by a density meter to ensure a reasonable ratio, and the immersion and extraction speed should be controlled. In order to obtain a satisfactory coating thickness and reduce defects such as air bubbles, it should be operated in a clean and temperature/humidity controlled environment. In order not to affect the dotting force of the material, the masking tape should be selected without adhesive residue and anti-static, if ordinary tape is selected, a deionization fan must be used.

Precautions for dip coating method:

The PCB assembly should be vertically immersed in the paint grains.

Do not immerse the connector unless it is carefully covered, the circuit board should be immersed for 1 minute until the air bubbles disappear, and then slowly take it out.

A uniform film is formed on the surface of the PCB. Most of the paint residue should be allowed to flow back from the board back to the impregnation machine.

The circuit board or components should not be immersed too quickly to avoid excessive air bubbles.

If there is crusting on the surface after dipping and re-application, remove the epidermis and continue to use it

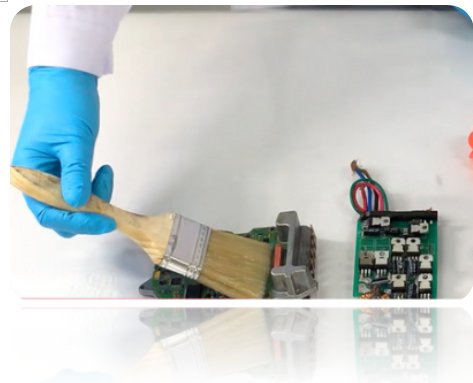

Conformal paint brushing method

Brushing is the easiest method of application. It is usually used for local repairs and repairs, but can also be used in laboratory environments or small batch prototypes/production, generally where the coating quality requirements are not very high.

Advantages of the brushing method: almost no investment in equipment fixtures, saving coating materials, and generally no masking process.

The disadvantages of the brushing method: narrow scope of application, the lowest efficiency, the whole board brushing has a masking effect, poor coating consistency, due to manual operation, it is easy to appear bubbles, ripples, uneven thickness and other defects, and requires a lot of manpower.

Notes:

Before brushing, first make sure that the diluted product is fully stirred, and leave it for 2 hours is the best.

The container for conformal coating should be made of metal or plastic, not wood or PVC, because it will produce a chemical reaction, corrode the container and destroy the product.

Clean and dry the plate to remove moisture and moisture.

Dust, moisture and oil stains must be removed from the surface of the object to be coated, and thorough cleaning will ensure that the corrosive residue is completely removed and the conformal coating adheres well to the surface of the circuit board.

The choice of brush is also very important, because the product is not insulated before curing, so choose a brush that is anti-static and does not shed, such as a high-quality natural fiber brush.

When brushing, the plate should be placed as flat as possible, and there should be no dew after brushing, and the brushing should be flat, and there should be no exposed parts, between 0.1-0.3mm.

The brushed circuit board should not be placed upside down, which will make the coating thin at the top and thick at the bottom, and still lie flat

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com