New energy electric vehicles are a mainstream trend to solve problems such as energy, environment, and urban transportation, and are also a major direction for the development of the future automobile industry. The development prospects of China's new energy vehicles are infinitely broad. In the past 10 years, the State Council has continuously increased its investment in funds, including special funds for technological progress and technological transformation, and support for key automobile manufacturers. Cities are also actively participating in the popularization and promotion of new energy vehicles in policies, development plans, infrastructure construction, consumption subsidies, and other links.

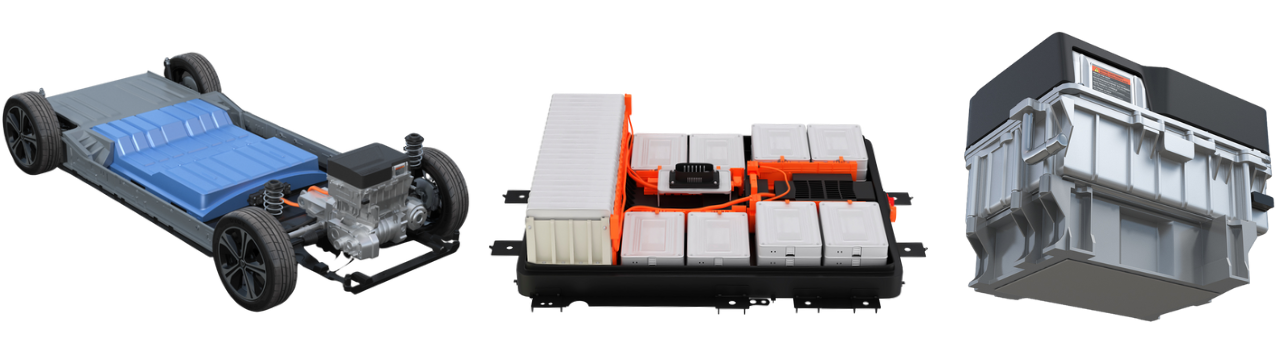

In the cost structure of pure electric vehicles (EVs), electric drive systems (including power battery systems and motor drive systems) account for more than 50% of the whole vehicle. Among them, lithium batteries are one of the keys, so there is a call for "those who get lithium get the world". Adhesive is one of the core factors to achieve stable, efficient, long-lasting and safe operation of electric drive systems.

Beginor Material adhesive can meet the rework process of lithium battery frame sealing, and has good waterproof performance and sealing ability. The positioning protection of the BMS battery management system and the excellent thermal conductivity and electrical insulation performance fully meet the fixed and thermal conductivity requirements of pouch and prismatic batteries

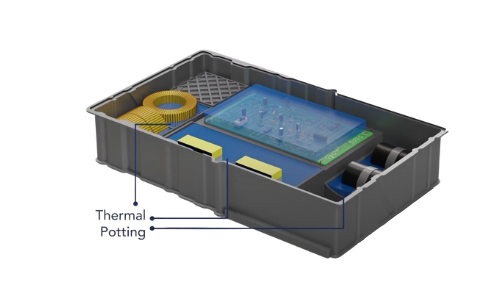

【Lithium battery potting】

· Low density, light weight and non-foaming · Excellent electrical insulation at high temperatures |  |

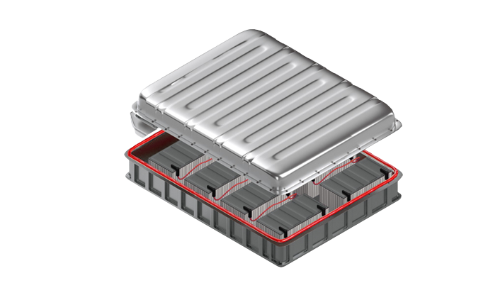

【Battery pack seal bonding】

| · Strong adhesion to various substrates · Excellent aging and chemical resistance |

【Thermal conduction between the bottom of the battery and the compartment】

TCMP 8820 · 1:1 Hybrid (Thixotropic) · Thermal conductivity 2.0 W/mK |  |

【IGBT Potting】

| BEGEL 8606 · Excellent protection · Temperature resistance -50-220°C |