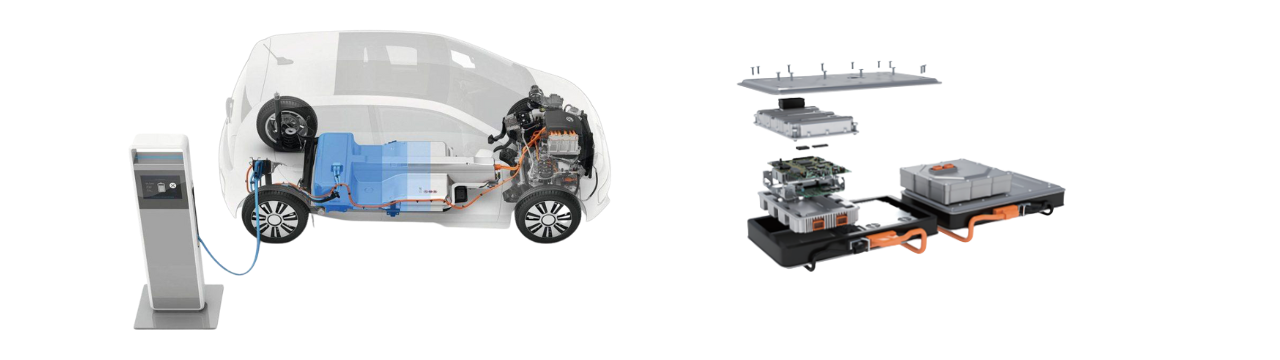

The electronic control system of new energy vehicles is a device that controls the drive motor of the vehicle. In new energy vehicles, due to the application of power electronics technology, its electrical system has undergone great changes, from the traditional low-power and low-voltage auxiliary electrical devices to the energy-saving, environmentally friendly, high-efficiency and low-noise electric transmission electrical devices of new energy vehicles, which has become the replacement of traditional automobile engines and gearboxes, and directly determines the main performance indicators of pure electric vehicles such as climbing, acceleration and maximum speed

Composed of electronic control system

The electronic control system of new energy vehicles is mainly composed of inverters, drivers, power modules, controllers, protection modules, heat dissipation system signal detection modules and other components, among which the inverter, driver and controller are the core components of the electronic control system:

(1) Inverter: controls the current of the drive motor, which is mainly composed of IGBT (insulated gate bipolar transistor) power module;

(2) Starting module: converting the control signal of the microcontroller to the motor into the driving signal of the driving power inverter, and realizing the isolation of the power signal and the control signal;

(3) Controller: It mainly includes the microprocessor and its smallest system, which is the monitoring circuit of the motor current, voltage and other states, the protection circuit and the communication circuit for the data interaction of the controller, battery management system and other external control units. The control software implements the corresponding control algorithm according to the characteristics of different types of motors.

The main reasons for the use of adhesives in the electronic control system of new energy vehicles are as follows:

1. Fix and protect electronic components: There are many electronic components in the electronic control system of new energy vehicles that need to be installed on the circuit board. The use of adhesives can hold these components in place, preventing them from loosening in motion or vibration, while protecting them from the outside environment.

2. Prevent electronic components from falling off: The working environment of the electronic control system of new energy vehicles is relatively harsh, and there are various influencing factors such as temperature, humidity, and vibration. If the electronic components are not fixed properly, it is easy to fall off, which will affect the normal operation of the whole system. The use of adhesives can effectively prevent this from happening.

3. Fill the gaps: The gaps between electronic components may cause interference in electronic signals and affect the stability and reliability of the system. The use of adhesives can fill these gaps and reduce the likelihood of interference with electronic signals.

4. Improve the heat dissipation effect: the electronic components in the electronic control system of new energy vehicles will produce heat for a long time, and the use of adhesives can closely connect the heat sink and the electronic components to improve the heat dissipation effect and ensure the long-term stable operation of the system.

In short, the use of adhesive can ensure the stability, reliability and safety of the electronic control system of new energy vehicles, and is an indispensable auxiliary material

BEGINOR Material adhesives provide adhesive solutions for the electronic control system of new energy vehicles

BEGINOR Material For a full range of multi-series product lines, sealants, potting castables, structural adhesives, three-proof coating adhesives, high-performance thermal interface materials and other products, which are widely used in new energy vehicles, so that new energy vehicles can maintain their reliability in the face of high and low temperature impacts caused by low temperature, vibration, climbing, low speed and other working conditions in the face of complex application environments

Inductive potting | Current sensors | EMC cores |

|  |  |

BESIL 8230(15#) · The two-component 1:1 is easy to operate · Good waterproof and thermal conductivity | BEPU 6608 · 100:16 Low viscosity potting · Medium hardness is good on the surface | BEEP 6225(8#) · Two-component medium to low viscosity · Good toughness and good adhesion |

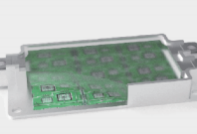

PCB rugged

| BECOAT 9060 · UV+ moisture curing · Complies with UL 94 V-0 | BECOAT 9007 · Single-component easy handling · Temperature resistance -60-200°C |

BECOAT 9333 · Resistant to moisture, dirt, etc · Temperature resistance -60-260°C | BECOAT 9001 · Low viscosity and good flowability · No yellowing, no oil seepage, excellent performance |

IGBT/SIC modules

| BEGEL 8606 · Excellent protection · Temperature resistance -50-220°C | BEGR 1130 · Thermal grease · Thermal conductivity 3.0W/m.K |

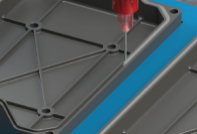

Power device heat dissipation

| TCMP 50#/60# Thermally conductive gel · Good gap filling capacity and low thermal resistance · Thermal conductivity 5.0-6.0 W/mk |

Housing bonded sealing

| BESIL 8530 2 · FIPG & CIPG · Excellent resistance to alternating cold and hot properties |

BESIL N9339 · FIPG · Excellent anti-aging properties | BESIL 9435 · FIPG & CIPG · One-component thixotropy, heat curing |

Component bonding and fixing

| BESIL 9320 · Elastic, non-yellowing · Thermal conductivity2.0W/mk |

BESIL 9337 · Good extrusion and high thermal conductivity · Temperature resistance -60~200°C | BESIL 9550 · One-component semi-thixotropic fluid · No primer required, fast heat curing |