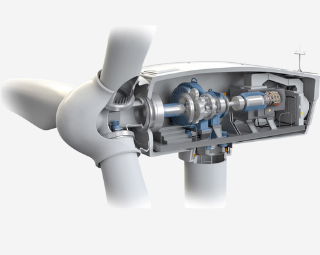

Converting wind energy into electricity is currently the most important way to use wind energy. In wind turbines, turbine blades are designed to capture kinetic energy in the wind. The rest of the structure is almost exactly the same as a hydroelectric unit: when the turbine blades capture the wind energy and start turning, they turn the shaft between the rotor center and the generator. Generators convert rotational energy into electricity. By its very nature, generating electricity through the wind is the transfer of energy from one medium to another.

A wind turbine is an electrical device that converts wind energy into mechanical work, which drives the rotor to rotate and finally outputs alternating current. Wind turbines are generally composed of wind turbines, generators (including devices), direction adjusters (tails), towers, speed limit safety mechanisms and energy storage devices.

BEGINOR Material Adhesive solutions for wind turbines

【Motor stator potting】

| BESIL 5295 (7#) A/B Additive Silicone Encapsulant » Two-component additive silicone rubber » Low hardening shrinkage » Excellent high temperature electrical insulation and stability » Excellent adhesion, the longer the cure, the better the adhesion » Good waterproofing and moisture resistance » Flame retardant version, UL V-0 |

BESIL N9339 silicone adhesive sealant » Excellent chemical resistance, low odor and good adhesion » Low volatile content does not exceed 500ppm, no corrosion and no fog in a closed environment » Resistant to moisture, dirt and other atmospheric components » Relieves mechanical stress and tension caused by mechanical, thermal shock and vibration » Excellent outdoor aging with a service life of up to 20-30 years » Stable mechanical and electrical properties between -60 and 300°C |  |