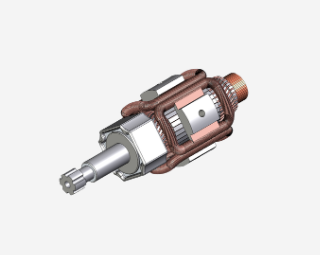

The precision of the motor control system depends on the requirements of the system. Some applications demand very high precision, such as industrial robotics or filling production lines. The motors in filling production lines must be precisely controlled, and to achieve high-precision motor control, it is essential to determine the speed, direction, and position of the rotor. Efficient and optimal responses are obtained through adjustments. Therefore, selecting the right adhesive product for the electronic control system is crucial. With the aggravation of energy crises, resource depletion, and environmental pollution, China has designated new energy vehicles as a strategic emerging industry. The on-board charger, as a crucial component of electric vehicles, possesses both theoretical research value and significant engineering application value.

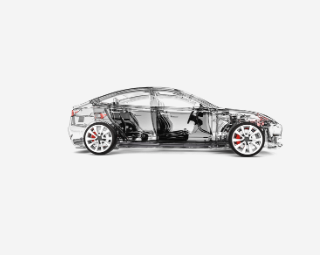

Adhesive solutions for automotive motors

As one of the key components on the new energy electric vehicle, the on-board charger converts the alternating current into the direct current required by the electric vehicle power battery to ensure that the battery can be fully charged safely and automatically, which determines the charging efficiency of the electric vehicle. As we all know, the use environment of new energy vehicle motors is complex, and it has to face the impact caused by various working conditions such as high temperature and low temperature, vibration, climbing, high speed and low speed, which requires the packaging material to maintain its reliability in the case of high and low temperature impact while having good thermal conductivity |

|

BESIL 8230 Series A/B thermally conductive potting silicone ♦ Two-component additive molding silicone rubber ♦ 1:1 mixing ratio ♦ Low hardening shrinkage ♦ Excellent high-temperature electrical insulation and stability ♦ The thermal conductivity can be 0.7~4.0W/m.k | Thermally conductive cement TCMP 25#/ 35#/60#

♦ plastic silicone thermally conductive cement, ♦ Thermal conductivity 2.5 ~6.0 W/m.K ♦ The minimum flattening gap thickness can reach 0.12mm ♦ Freeness< 0.1% (200°C 24hrs) |

electronic control system adhesive solutions

【Circuit board rugged】

| BESIL 9002 Silicone coating adhesive ♦ 100% solids in one component, 28,000 CPS ♦ A thin layer of 1-2mm is applied on the PCB board ♦ Flame retardant UL HB rating

BECOAT 9060 Silicone coating adhesive ♦ 100% solids in one component, 480 CPS ♦ Contains fluorescent indicator, hardness A20, reworkable ♦ Coating thickness 40-100μm ♦ Flame retardant UL recognized |

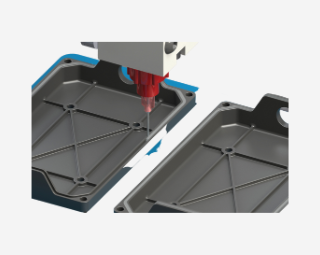

【Electric control box sealing】

| BESIL 9435 Heat-curing silicone ♦ One-component thixotropic paste ♦ 120°C 30mins heating curing ♦ Good compression set, suitable for CIPG and FIPG BESIL N9339 Room temperature curing silicone ♦ One-component thixotropic paste ♦ Curing at room temperature, curing at 24hr with a thickness of 3mm ♦ Good compression set, suitable for CIPG and FIPG |  |

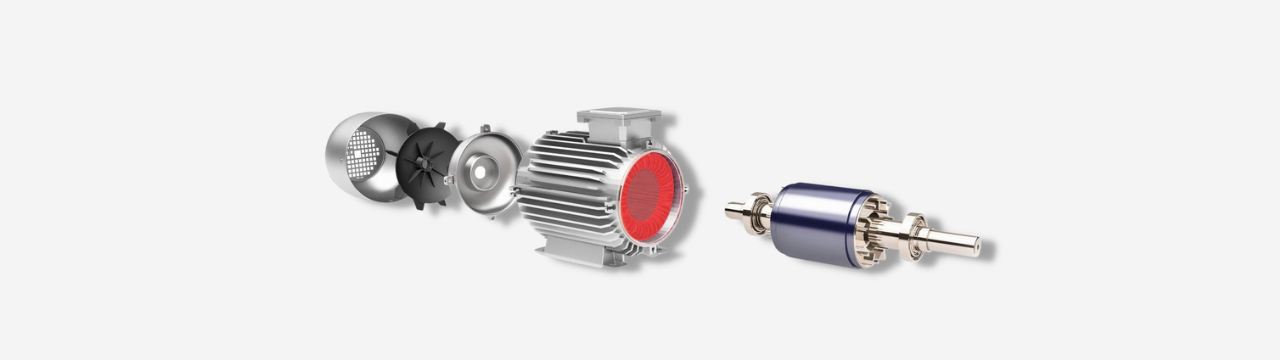

BEGINOR motor stator potting solution

| BEEP 6115(2#) Thermally conductive and temperature-resistant epoxy potting compound ♦ Two-component high-viscosity viscous body with a 100:70 mass ratio ♦ Thermal curing, high TG, high thermal conductivity ♦ The resistance to temperature shock at high and low temperatures is very good BEEP 6225(62A#) Thermoset epoxy encapsulant ♦ The two-component paste flows slightly ♦ Heat-curing, high TG ♦ Good toughness and impact resistance |