The structure of the vehicle display is generally composed of a display screen, a controller, a power supply, etc., in which the display screen can display various information of the car, the controller can control the display content of the display, and the power supply can provide power for the display screen.

Compared with the display screen of other consumer electronics, the working environment of the vehicle display screen is relatively complex, in the process of car driving, the vehicle display often has to work in the sun, and there are certain bumps, which will have a certain impact on the vehicle display. Therefore, automotive displays need to use adhesives that can improve the structural strength of the display, as well as improve the durability and reliability of the display. Adhesives can effectively fix the various parts of the display screen together, making the structure of the display more solid, thereby improving the service life of the display

The application scheme of beginor adhesives in automotive displays

【Screen and frame bonding】

Optical bonding process used to attach a protective, transparent overlay screen to the underlying LCD panel. Using this lamination method usually eliminates the air gap between the two layers and can greatly improve the visibility of the screen

| BEGEL 8506A/B Silicone Liquid Optical Adhesive ◆ High light transmittance ◆ Low yellowing ◆ Room temperature curing or heat curing ◆ High toughness and surface viscosity |

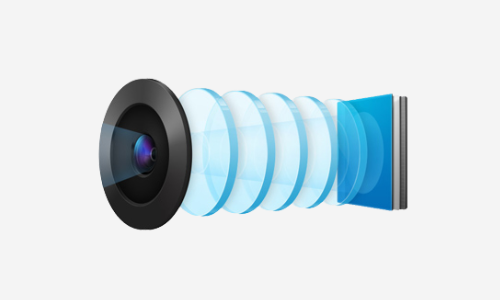

【Camera module bonding】

BEEP 6618 one-component, low-temperature epoxy adhesive ◆ It has high adhesion ◆ Low water absorption ◆ It can be applied to the bonding of a variety of materials ◆ It has good storage stability |  |

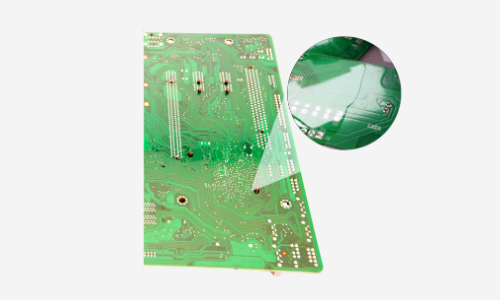

【【PCB Rugged】

| BECOAT 9060 series silicone conformal adhesive ◆ Transparent one-component, easy to operate ◆ Good adhesion, no corrosion. ◆ Low viscosity eco-friendly fluid, solid content 100% ◆ Easy to brush, spray, dip coating a variety of processes, fast curing speed |

【Chip underfill】

BEGEL 9500 Chip Encapsulated Gel ◆ One-component direct dispensing, no mixing required ◆ No need for ultra-low temperature storage ◆ High purity, low ring content is very small ◆ Low viscosity and excellent foaming ability ◆ It can work in a wide range of operating temperatures, -80-230 °C |  |