According to the plasticizer content, PVC plastic is often divided into: rigid PVC, plasticizer content less than 10%; semi-rigid PVC, plasticizer content of 10-30%; soft PVC, plasticizer content 30-70%

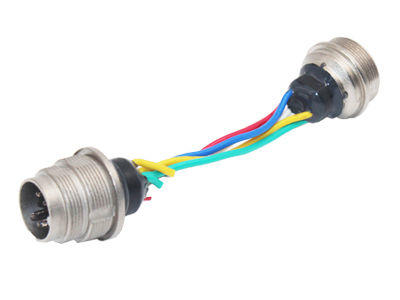

Type of PVC wire bundles

According to the plasticizer content, PVC plastic is often divided into: rigid PVC, plasticizer content less than 10%; semi-rigid PVC, plasticizer content of 10-30%; soft PVC, plasticizer content 30-70%.

Industrial PVC has no obvious melting point, starts to soften at about 80 °C, heat distortion temperature (at 1.82 MPa load) is 70-71 ° C, starts to flow at 150 ° C under pressure, and begins to slowly release hydrogen chloride, resulting in polymerization Vinyl chloride discoloration (from yellow to red, brown, and even black).

Application of silicone sealant and potting compound for PVC wire bundles

One-component room temperature curing Silicone sealant Besil 9333

Features:

a, micro-flowing paste , can better fill the gap between the wire harness, fill the gap between the wire harness and the lead-out hole

b, curing time is fast, early solid during 2-3 hours

Application: Harnessing from the plane and surface position

Applicable: multiple bundles of soft wire harnesses, cable sheaths for multi-wire bundles

![]()

![]()

Two-component Silicone potting compound Besil 8130

Features:

a, low viscosity potting

b, room temperature curing has adhesion to most polar substrates

c, curing time can adjust the proportion of curing agent according to requirements

Application: Lead bonding of PCB board control board, large area filling of leads and cavities

Applicable: independent hard cable or soft cable

Two-component epoxy potting compound Beep 6112

Features:

a, low viscosity potting

b, flexible elasticity after curing, can be bent freely without breaking

c, hardness does not change after long-term aging

Application: Connector sealing, lead and potting of small area cavities

Use: independent or multi-beam soft hard wire harness or cable