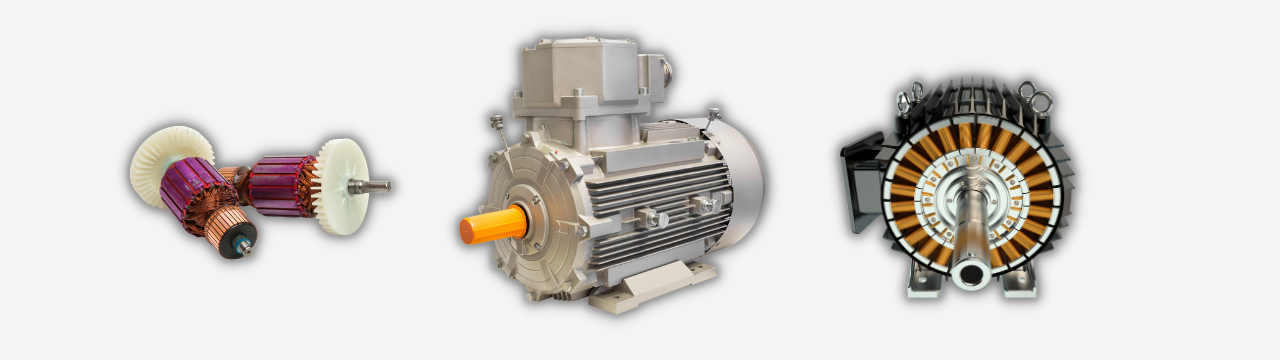

Industrial motors include general motors and micro motors, which are common equipment in industrial applications. In recent years, with China's active deployment of policies to promote the transformation of industrial structure, the manufacturing industry has turned to the direction of green and sustainable development, and promoted the development of high-efficiency and energy-saving motors and product substitution.

As an electric motor manufacturer, you need to face demanding market requirements to improve durability, reduce manufacturing costs, and improve motor efficiency. Worship adhesive solution provider, provide the whole value chain of motor adhesive solutions, improve the efficiency of the motor to provide solutions

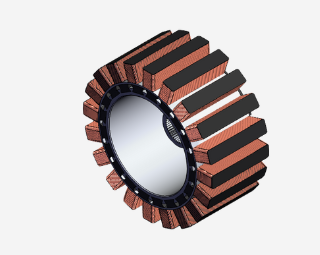

Bonding of motor magnets

High-speed permanent magnet synchronous motor is a new type of high-efficiency and energy-saving product, which has the significant advantages of high stability, high efficiency, simple structure, flexible and diverse shape and size of the motor. The motor magnets can be bonded using BEEP 621 one-component epoxy adhesive

| BEEP 621 one-component epoxy adhesive » Black and solvent-free » Good toughness and impact strength » Excellent adhesion, electrical, moisture resistance and mechanical properties » Most substrates including glass, metal, ceramic, etc., have high bond strength |