With the development of China's automobile industry, adhesives for automotive oil filters have also developed. With the requirements of China's automobile industry such as lightweight, dryness and vibration reduction, low emission, low VOC and low odor, the adhesive for automotive oil filter has also had some new characteristics and development directions. From the initial single product, it has developed into a rich and diverse product line. From the original toxic and harmful solvent adhesive-based adhesive to today's environmentally friendly and non-toxic hot-melt adhesive and two-component PU adhesive. With the development of the filter industry, its filter adhesives have higher and higher bond strength, lower odor, easier operation, faster curing, more suitable for automation, higher high temperature resistance and lower low temperature resistance. Filter paper adhesives, which are mainly based on expanded polyurethane (PU) elastomers, can be self-molded to replace the rubber sealing ring on the end cap of the steel plate and the end cap, and synthesize it with the filter media

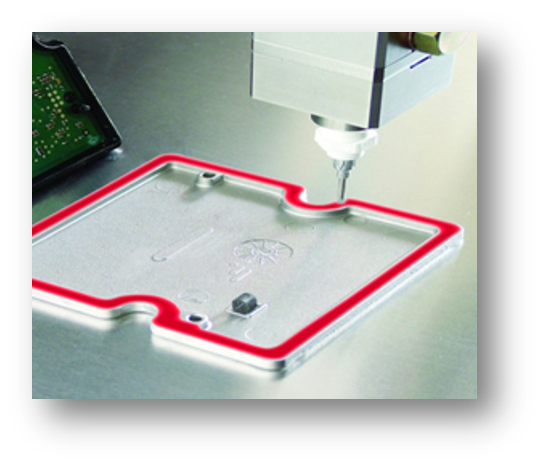

Automotive oil filter adhesive application scheme

BEEP 6220 two-component epoxy adhesive is designed for metal bonding, SMC fiberglass bonding, aluminum honeycomb panel splicing and core bonding of motor products, ceramic membrane module sealing, soft magnetic unit potting, high temperature sensor potting, etc |

|

【End Cap Bonding and Fixing】

| ◆ Resist moisture, dirt and other atmospheric components ◆ High strength, excellent adhesion ◆ Good anti-pollution and low surface pretreatment requirements ◆ No solvent, no curing by-products ◆ Excellent resistance to high and low temperatures, -50°C-150°C ◆ Resistant to transformer oil, low attenuation ◆ Good adhesion to glass fiber cloth and steel plate |