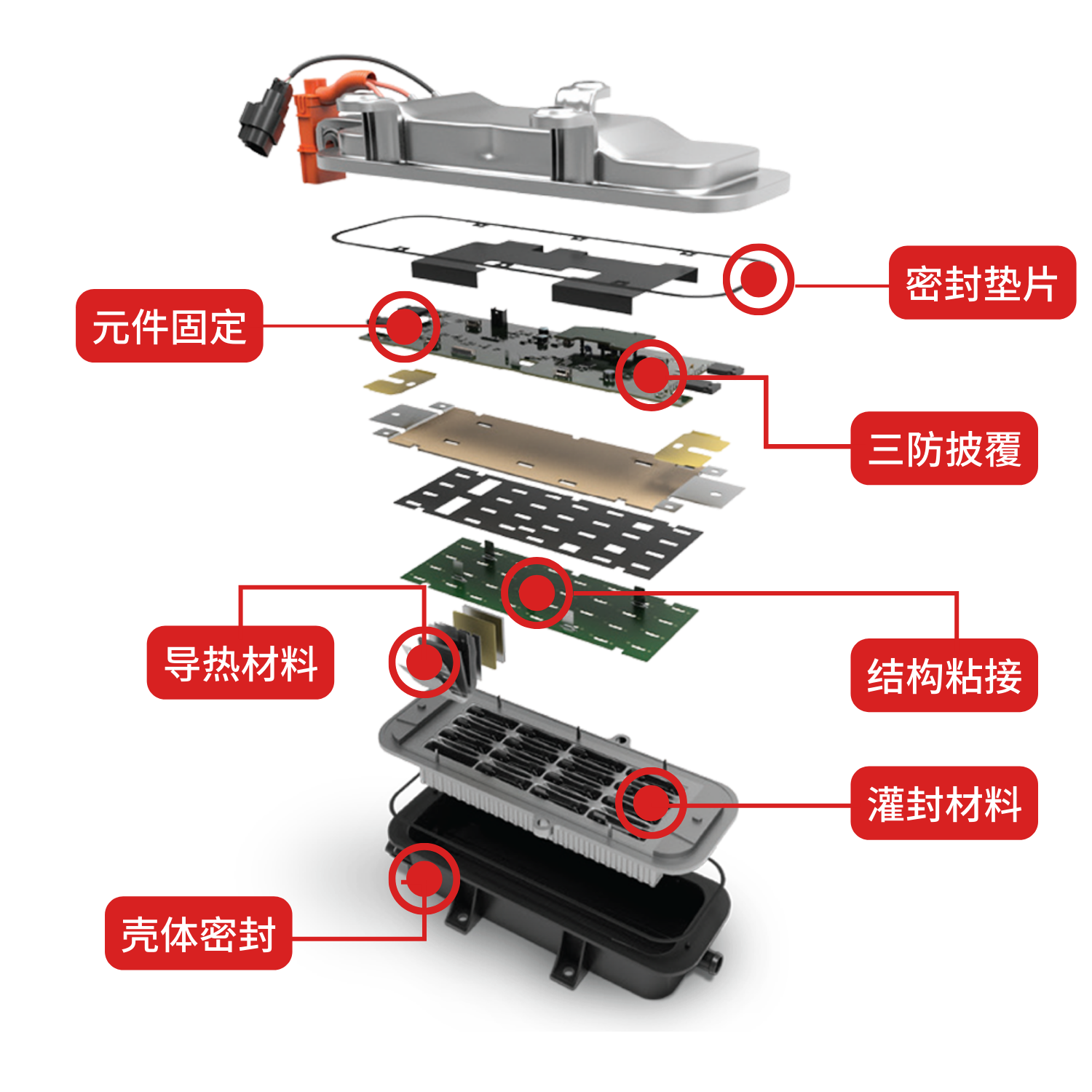

Key engineering challenges for EV powertrain components include efficient thermal management, integrated electrical systems, miniaturization, reducing overall vehicle weight, and ensuring safe and reliable vehicle performance. At the same time, from a business point of view, the price of electric vehicles needs to be reduced by reducing the overall system cost.

Generally speaking, the adhesive used in the three-electric system of new energy vehicles needs to have the following characteristics:

1. High temperature and low temperature resistance, able to maintain stability in extreme environments;

2. It has good sealing and waterproof performance to protect electronic components from moisture and corrosion;

3. It has high durability and anti-aging ability, and can maintain the performance of glue for a long time;

4. It is not corrosive to electronic components and can maintain electrical insulation.

Commonly used adhesives for new energy vehicle three-electric systems include silicone adhesive, polyurethane adhesive, epoxy resin adhesive, etc. When choosing a glue, it is necessary to consider it comprehensively according to the specific use scenarios and requirements to ensure the performance and use effect of the glue.

Automotive Electronics

Automotive Electronics

Electric Vehicle

Electric Vehicle

Consumer Electronics

Consumer Electronics

Electrical System

Electrical System

Electrical Equipment

Electrical Equipment

Home Appliances

Home Appliances

Semiconductor

Semiconductor

Connector

Connector

Sensor

Sensor

Motor

Motor

Industry

Industry

medical

medical

Lighting

Lighting