With the rapid development of modern science and technology, the selection of aerospace materials is more stringent, launch vehicles, intercontinental missiles, space shuttles and other space launch vehicles are developing in the direction of light weight, good reliability, long life and low energy consumption, and the use of adhesives with excellent performance and their corresponding bonding technology has become one of the effective sections of spacecraft to improve efficiency. The use of adhesives in aerospace products has become more and more widespread, mainly because aerospace products mostly use light alloys, honeycomb structures and conforming materials. In addition, the use environment of aerospace products is harsh, and the requirements for adhesives are also higher, which need to be able to withstand environmental tests such as ultra-high temperature, ultra-low temperature, temperature alternation, high vacuum, thermal cycling, ultraviolet rays, charged particles, micrometeorites, and atomic oxygen

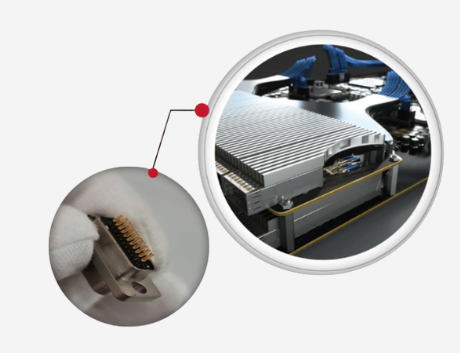

Aerospace connector bonding and fixing applications

Aerospace connector welding temperature resistance seal, the use of Baigo two-component epoxy potting compound, excellent adhesion, crack resistance, good toughness, high hardness, excellent electrical insulation, stability, very low expansion coefficient

【Welding temperature resistance sealant】

| ◆ Low linear expansion coefficient ◆ Curing shrinkage is small and viscosity is low ◆ Temperature resistance class H ◆ High hardness and good toughness ◆ Excellent electrical insulation and thermal stability ◆ Temperature resistance range: -50-200°C |

BEEP 6902 ◆ Excellent adhesion and crack resistance ◆ Good toughness and high hardness ◆ Excellent electrical insulation and stability ◆ Very low coefficient of expansion ◆ High Tg point, can be used at 200°C for a long time ◆ Good waterproof, moisture-proof, very low water absorption | BEEP 6220 ◆ Good adhesion to various substrates ◆ Low viscosity, easy to operate ◆ High shear strength and peel strength ◆ Good impact strength ◆ Good high temperature resistance ◆ Excellent oil and acid and alkali resistance |