Shanghai Beginor Material specializes in the production of potting adhesive and is one of the important manufacturers of epoxy potting adhesive in China.

After curing through the potting process, the components can be reduced by external environmental conditions, ensure the good operation of the components in the standard working environment, and improve the normal stability and service life of the components

Beginor Material epoxy potting compound has superior environmental protection properties such as insulation, moisture-proof, dust-proof, mildew-proof, shock-proof, anti-leakage, anti-corona, anti-corrosion, anti-salt spray, anti-acid and alkali, anti-sulfurization, anti-aging, high and low temperature impact resistance, high humidity and high temperature resistance, and flame retardant. Different encapsulant applications have different performance requirements, resulting in different synthetic materials and formulations, as well as synthesis processes

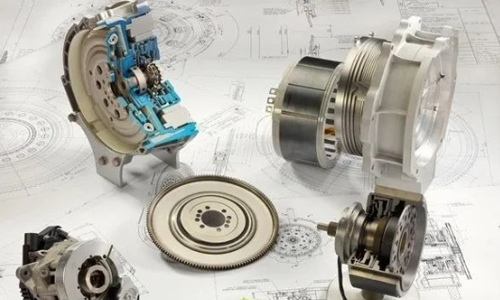

The three major parts of new energy vehicles are mainly motors, electronic controls and batteries, among which the motor can be said to be the core technology of new energy vehicles

An electric motor is a device that converts electrical energy into mechanical energy. It uses an energized coil (that is, the stator winding) to generate a rotating magnetic field and acts on the rotor (such as a squirrel cage closed aluminum frame) to form a magnetoelectric dynamic rotational torque

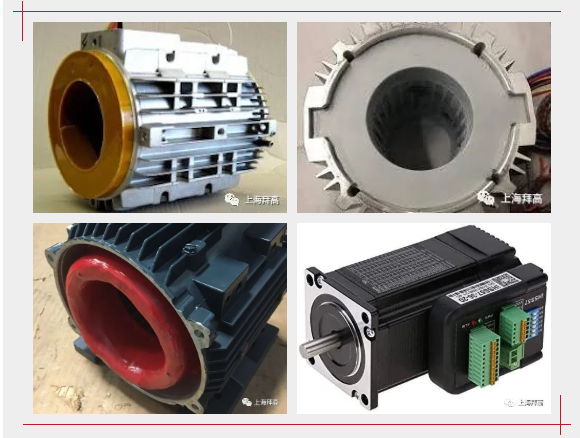

Obviously, the most important components in the motor are the stator and the rotor, the stator is the motor or the stationary part, the stator is composed of three parts: the stator core, the stator winding and the base. The main function of the stator is to generate a rotating magnetic field, while the main function of the rotor is to be cut by magnetic field lines in the rotating magnetic field to produce an output current.

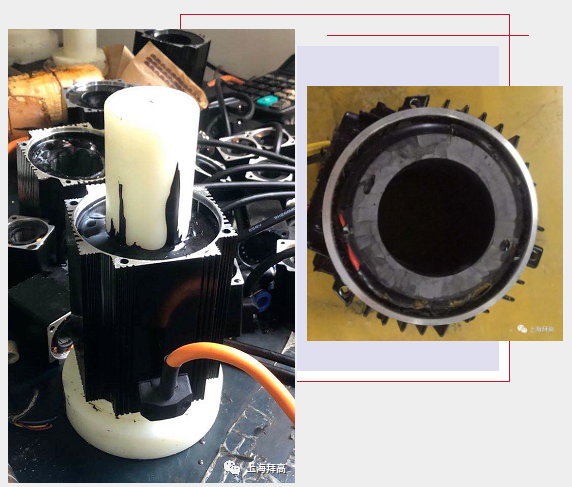

Potting strengthens the integrity of electronic devices and improves the resistance to external shocks and vibrations; Improving the insulation between internal components and lines is conducive to the miniaturization and lightweight of devices; Avoid direct exposure of components and circuits, improve the waterproof and moisture-proof performance of the device, and improve the performance and stability parameters

Beginor Material Epoxy Encapsulant Solution for Motor Stator Potting, BEEP 6112A/B Two-Component Solvent-Free Ambient Curing Epoxy Encapsulant

BEEP 6112 epoxy encapsulant is a suitable encapsulant for the drive electronic stator. After potting to the stator of the drive motor, it can better help the drive electronics to dissipate heat; Excellent electrical insulation properties, electromagnetic compatibility and can also resist high voltage and electromagnetic interference; The stator is encapsulated in a silicone elastobody, which can also resist the erosion of atmospheric environments such as water vapor and salt spray, and at the same time, to a certain extent, can also effectively resist vibration and impact forces

Product characteristics of BEEP 6112 epoxy encapsulant

◆ Flame retardancy of 94V-0. Excellent adhesion and crack resistance

◆ Excellent electrical insulation and stability

◆ Good waterproof, moisture-proof, very low water absorption

◆ Good temperature resistance, short-term temperature resistance of 150 degrees

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com