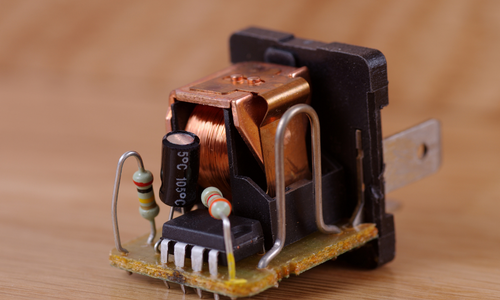

Relay (Relay) is an electronic control device, it has a control system (also known as the input loop) and the control system (also known as the output loop), usually used in the automatic control circuit, it is actually a kind of "automatic switch" to control a larger current with a smaller current. Therefore, it plays the role of automatic adjustment, safety protection, and conversion circuit in the circuit. As one of the four major electronic components, it is widely used in remote control, telemetry, communication, automatic control, mechatronics and power electronic equipment.

Relays are generally composed of iron cores, coils, armatures, contact reeds, etc. As long as a certain voltage is added to both ends of the coil, a certain current will flow through the coil, resulting in an electromagnetic effect, and the armature will overcome the tensile force of the return spring under the action of electromagnetic force attraction and attract to the core, thereby driving the dynamic contact of the armature to engage with the static contact (normally open contact).

When the solid-state relay is working normally, there is a certain power loss on its internal chip, and this loss power is mainly determined by the product of the output voltage drop of the solid-state relay and the load current, which is consumed in the form of heat. Therefore, the quality of heat dissipation directly affects the reliability of the solid state relay, and the excellent thermal design can avoid failure and damage caused by poor heat dissipation. In order to solve the problem of heat dissipation, potting materials are generally used at the bottom of the relay to conduct heat and seal to prevent the corrosion of pollutants such as dust and moisture

In order to make the relay have good performance after potting the above-mentioned functional elements, the potting compound needs to have the following characteristics:

1. High dielectric strength, good insulation performance, dielectric strength greater than 25KV.

2. Good thermal conductivity, heat dissipation, thermal conductivity greater than 1.0.

3. Good anti-aging, good thermal stability, and not easy to age after potting and curing.

4. Good sealing, its excellent sealing makes electronic products reduce vibration, reduce noise, and enhance the stability of product circuits.

5. The waterproof and moisture-proof performance is good, and the electronic products after potting have excellent moisture-proof, waterproof, dust-proof, anti-corrosion and other effects.

6. After potting, it can be cured within 20 minutes, and the viscosity is high and not surplus.

7. Environmental protection and pollution-free, non-toxic products, in line with international environmental protection standards

solution

BESIL TCMP 8815 Liquid Thermally Conductive Gap Filler, Thermal Conductivity 2.0 W/mK, Thixotropic Low Stress Application, Designed to Provide Enhanced Thermal Management for Advanced Automotive Batteries, Automotive Electronics, Communication Equipment, etc., It Provides Enhanced Reliability and Rework Compared to Traditional Materials, Liquid Thermally Conductive Gel Gasket TCMP is a highly adaptable material that is easy to use, can eliminate assembly tolerances, makes production components almost low compressive force, and protects solder joints and other components. Liquid Thermal Gel Gasket is a two-component fast-curing liquid thermal gel gasket that can be perfectly reworked and repaired, significantly reducing overall costs, and automatically controlled feed that significantly reduces waste, again reducing overall costs, and is a two-component fast-curing liquid thermal gel gasket that can be fully automated for industrial 4.0 thermal interface materials

【Product Features】

▶ 1:1 hybrid (thixotropic)

▶ Low stress applications

▶ Easy to operate

▶ Heating accelerates the reaction

▶ Low hardness and microviscosity

▶ Platinum catalyzed and thus siloxane volatiles are extremely low

▶ ROHS-COMPLIANT, HALOGEN-FREE, REACH CERTIFIED

Differences in the interface filling of liquid caulk and thermal pads

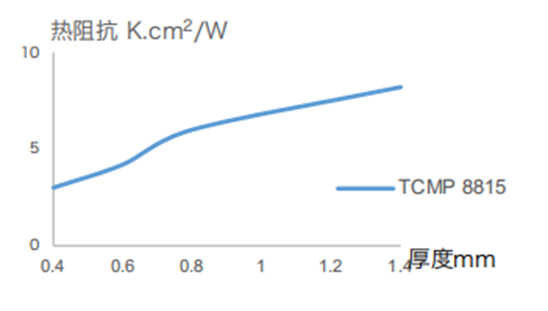

Curve of thermal resistance as a function of thickness

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com