PCB board is an indispensable component in electronic products, whether it is consumer electronics, home appliances, medical equipment, industrial machinery, automotive electronics, aerospace, etc., are inseparable from the existence of PCB board. With the development of lightweight and miniaturization of electronic devices, the design of PCB is getting smaller and smaller, but the work efficiency is indeed not bad at all, so the heat dissipation of PCB is also the most relevant problem of electronic products at present

At present, there are various solutions to the heat dissipation problem of PCB, and the more common one is the coating of thermal conductive materials, which can effectively reduce heat and protect components from damage. And today, Baigao will introduce you to vacuum bonding technology.

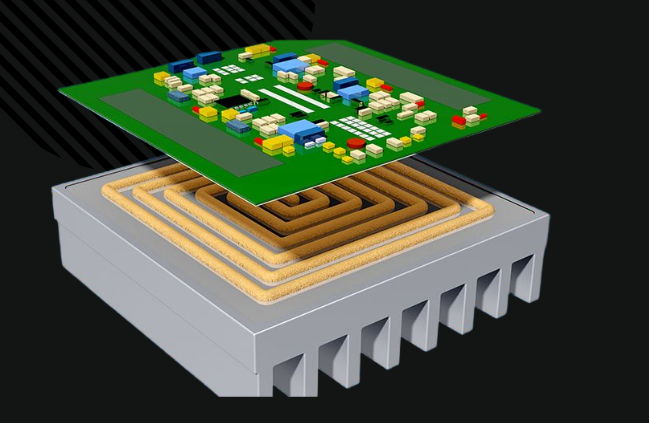

Vacuum bonding results in an even, smooth and bubble-free distribution of the thermally conductive adhesive, resulting in ideal heat dissipation. Unlike traditional bonding methods, which use pressure ejector rods to press the component onto the target substrate, in this method, the pressure is evenly distributed over the entire surface, preventing unnecessary stress formation on the component. This makes it possible to truly eliminate out-of-spec parts caused by factors such as cracking

Vacuum bonding method

Step 1: A thermally conductive adhesive with a high fill amount is potted into a heat sink in the form of concentric wires

Step 2: At this point, the applied binder does not completely cover the surface. The filler in the potting material not only provides reliable heat dissipation, but also defines the necessary gap (0.1 mm).

Step 3: The PCB, which is placed on top of the binder coating, is then inserted into a compact vacuum chamber. The size of the vacuum chamber has been deliberately designed to be small to ensure that the air can be evacuated quickly and efficiently.

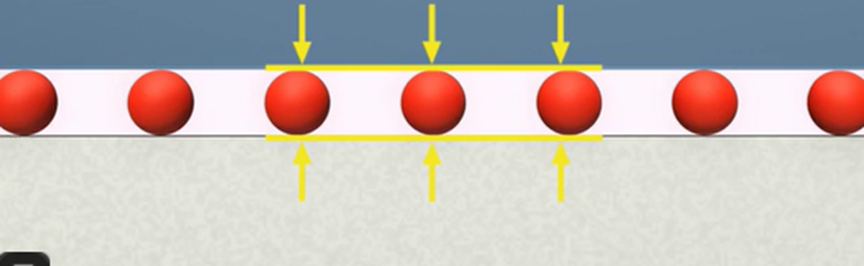

Step 4: When the resulting pressure is reduced to approximately 5 mbar, air is extracted from the perimeter of the component and in the space between the binder coatings

The vacuum chamber is then emptied, and at the same time, the joined components are exposed to atmospheric pressure. This pushes the PCB and heat sink closer together, but does not create any mechanical stress until the defined distance of the particles contained in the remaining binder remains the same

Product recommendations

Beginor Material Thermal Pad TP series thermal conductive and heat dissipating adhesives are composite materials of silicone rubber and glass fiber. It is flame retardant and is specially formulated for thermally conductive insulators. It is mainly used for electrical isolation of the power supply from the heat sink

【Product Features】

◇ Thermal conductivity: 1--6W/m.K

◇ Excellent mechanical and physical properties, flexible surface

◇ It has good heat dissipation

◇ Excellent cut resistance

◇ Non-toxic, resistant to damage by cleaning agents