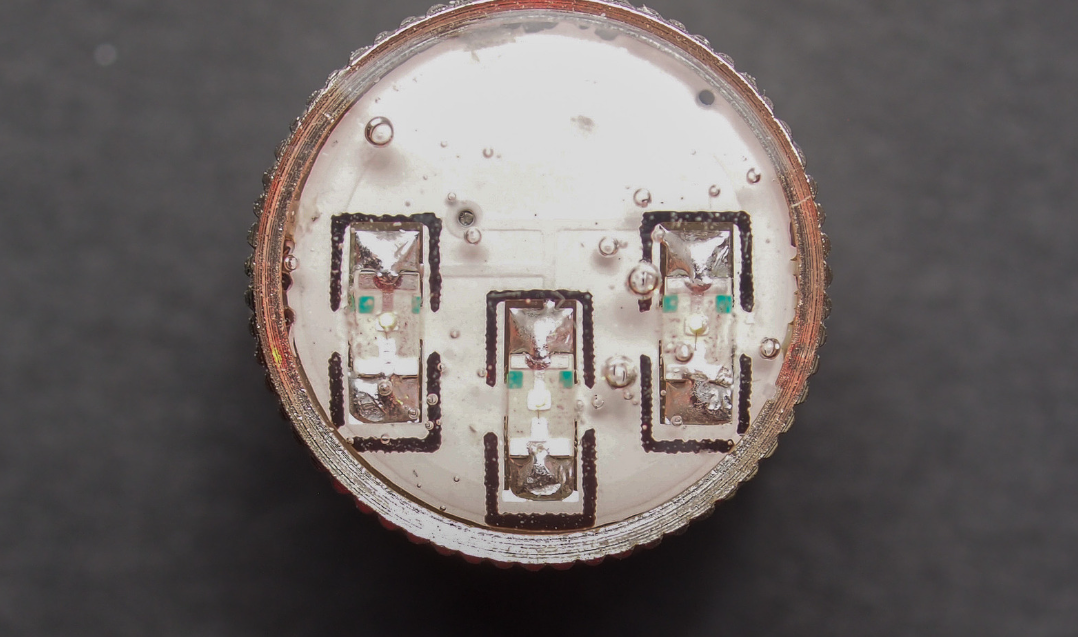

LED technology has increasingly replaced tried-and-tested light sources such as halogen spotlights and fluorescent lamps. In order to obtain high-quality lighting and a long service life, LEDs need to be potted several times. This is usually achieved through a vacuum process, as this is the only way to ensure that there are no air bubbles in the lamp and that the LEDs are protected from dust and moisture

LED are up to 90% more energy efficient than incandescent lamps and have a lifespan of up to 50,000 hours, plus: LEDs (light-emitting diodes) are considered the most efficient and promising lighting technology in the industry today. While traditional light bulbs faced a decline around 2008, other types of light sources, such as halogen spotlights, energy-saving lamps, and fluorescent lamps, were increasingly replaced by LED technology. They can be used in a variety of applications: LEDs were first used for signal lights and status indicators, but now they are mostly used in automotive engineering, architecture, house interiors and infrastructure lighting (e.g. street lights, traffic lights, LED backlit billboards and tunnel lights)

The potting process provides long-life, high-quality illumination

Using an accurate, high-quality potting process is critical to ensure long life and consistently high-quality illumination of LED components. This is especially important when LEDs are used outdoors, as they are exposed to a variety of harsh environments such as dust, moisture, UV rays, and temperature fluctuations. Even for integrated lighting systems for indoor residential use, potting quality and longevity are important. For example, materials that age when exposed to light are not suitable for optical LED potting. In addition, the properties required for the potting medium must also be considered, such as those related to color, hardness, water permeability, light conductivity, and high temperature stability.

Low-cost potting processes are also important in thermal management. While LEDs are more efficient than traditional light sources, they also generate heat. If this heat is not dissipated efficiently, the increased temperature will shorten the life of the LEDs and even lead to errors and failures in severe cases. Fluid thermal interface materials, such as gap fillers or thermally conductive binders, can be used to achieve an effective thermal management system.

What many people may not know is that accurate and repeatable dispensing and potting processes are even important for the production of OLEDs (organic light-emitting diodes). Organic light-emitting diodes contain multiple layers of organic film between two electrodes. These layers of film must be tightly sealed, otherwise they can be easily damaged by the action of oxygen. Therefore, a suitable potting system is required to potten a special binder onto the substrate and then combine them together

LED potting: Vacuum protection against dust and moisture

In order to protect LED diodes and associated electronic components from external influences, luminaire manufacturers have previously routinely used finished plastic covers and housings to protect them. Potting processes are increasingly being used, with the advantage that potted LEDs not only meet higher requirements in terms of tightness and mechanical stability, but also sometimes improve light properties, such as light color and dispersion, more than housings, provided that the right potting material is used. Reduced storage costs as well as reduced handling and assembly costs are additional advantages.

Not only can air bubbles in the material affect the quality of the light, but residual contaminants and moisture can also damage the diode. Therefore, the LEDs must be vacuum-potted. In addition to purely functional criteria, aesthetic criteria are equally important: When a glue filling process is used instead of a plastic housing, the potted resin is in direct visual view of the user or end customer. This reason alone requires that the appearance of the lamp must be perfect and free of air bubbles.

Product recommendations

BESIL 8230 two-component silicone thermally conductive potting compound can be used to potting the bottom of LED lamps, which can not only protect wires and circuit boards, but also waterproof and moisture-proof, high thermal conductivity, and extend the performance and service life of LED lamps

BESIL 8230 Black, White & Grey 2-Component Silicone Thermally Conductive Encapsulant Product Features: ◆ Two-component additive molding silicone rubber ◆ 1:1 mixing ratio ◆ Low hardening shrinkage ◆ Excellent high temperature electrical insulation and stability ◆ Good waterproof and moisture-proof

|  |

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com