The electric vehicle industry is growing rapidly, and automakers are working to reduce costs, shorten charging times, extend driving range and operating temperatures, and improve battery safety. Scientists are also working to develop new materials for the electric vehicle market that are formulated with better temperature resistance, higher durability, and a higher overall performance-to-weight ratio

As a leading polymer materials company, Beginor Material is doing its part to provide complete adhesive solutions to automotive OEMs and Tier 1 suppliers

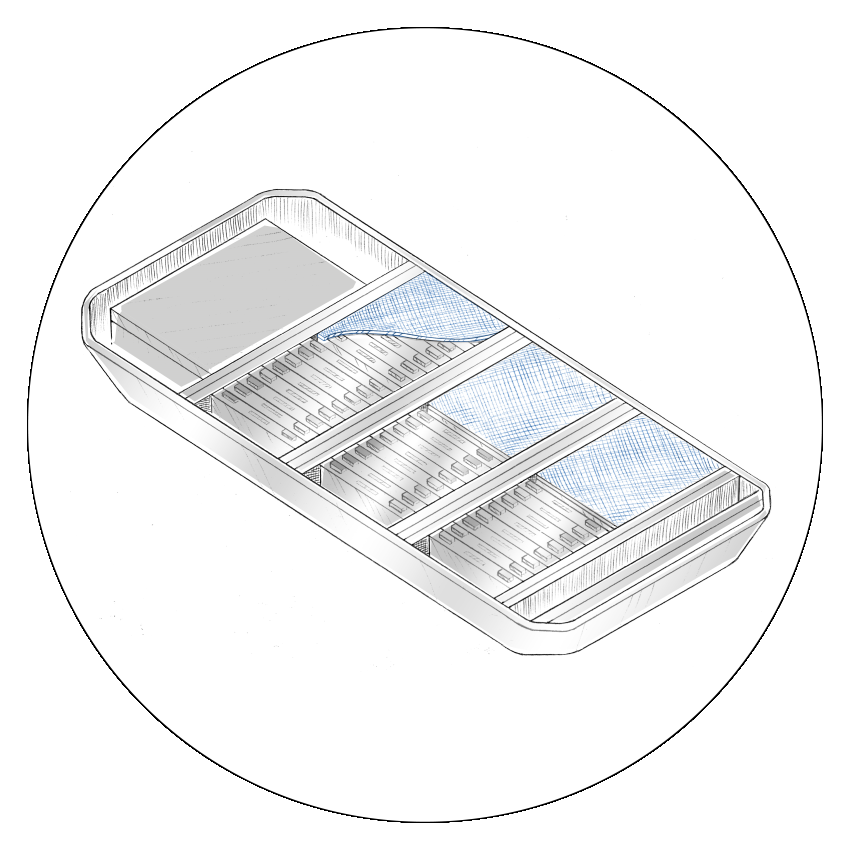

Glue deposits for adhesives

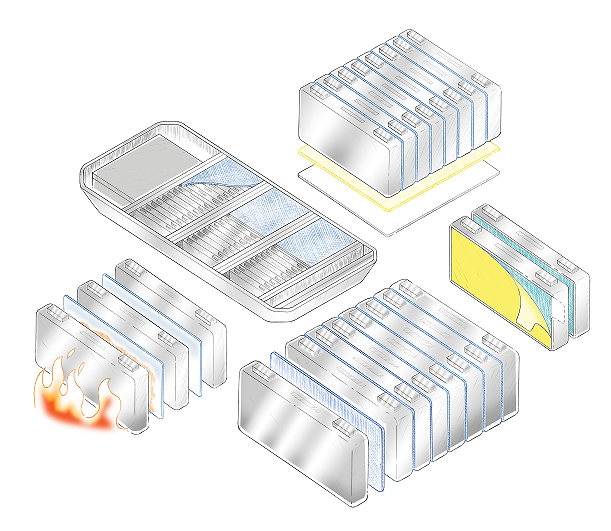

Seals and gaskets in EV batteries are used to protect the battery from environmental factors such as dust, moisture, and heat. They also help to maintain the integrity of the battery by helping to prevent electrolytes and other liquids from leaking out of the battery pack if it ruptures.

▶ Battery pack (upper and lower)

▶ Maintain entry points

▶ Cooling plates and liquid delivery systems

▶ Ventilation caps

▶ Module sealing

▶ Cells

▶ Endpoint isolation

EV battery gaskets and seals are an effective choice for preventing the ingress of environmental contaminants and providing thermal insulation for heat-sensitive components. They also provide fire protection and electromagnetic interference (EMI) shielding.

Product recommendations

TCMP 8820

▶ 1:1 Hybrid (Thixotropic)

▶ Thermal conductivity 2.0 W/mK

▶ Strong adhesion to various substrates

▶ Excellent aging and chemical resistance

▶ Excellent anti-aging properties

▶ Temperature resistance -60-300°C

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com