Why is PCB thermally managed?

1. The density of components on the surface of the PCB is high

The electronics industry is witnessing a trend towards thinner and smaller handheld devices and home appliances. That's why the space between components on an electronic PCB is getting closer together, making it harder for heat to get out of the PCB components

2. PCB needs higher power consumption

For smaller and more advanced devices, not only does the density increase, but the amount of information carried by the components increases, resulting in an increase in the power consumption of the components

These two main reasons have led to the increasing demand for thermal control in electronic PCBs to ensure product reliability and productivity. In short, devices that run at lower temperatures last longer and perform better

Learn about thermal resistance and heat transfer in PCB

Thermal resistance is a component-specific metric and one of the most important metrics to calculate in order to know the appropriate operating temperature for a typical PCB. The lower thermal resistance means that the PCB can withstand higher temperatures from the environment

Although TR is a fixed indicator of the component on the PCB, we can reduce the thermal resistance by adding some materials and equipment below the PCB or above the component to improve the heat transfer.

PCB Thermal Management Thermal Interface Materials

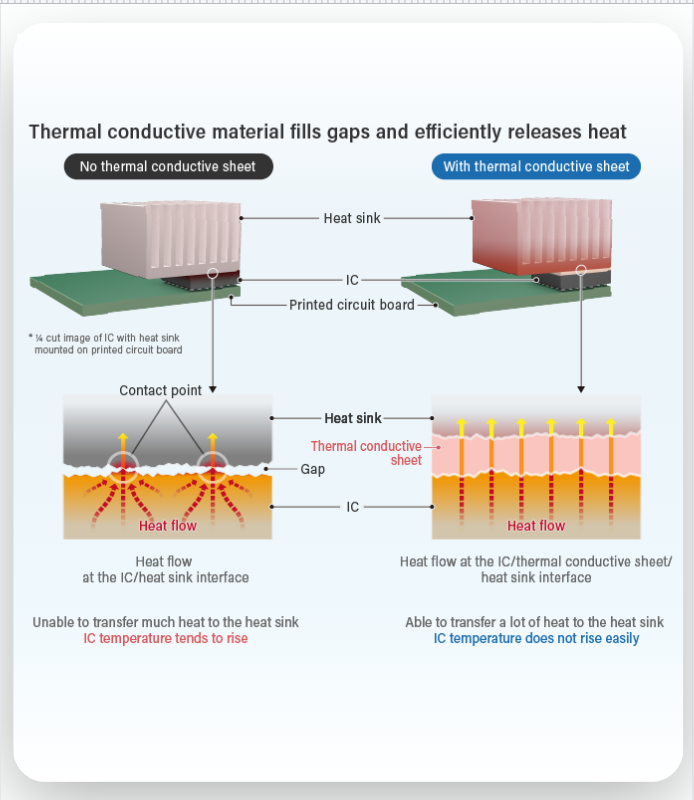

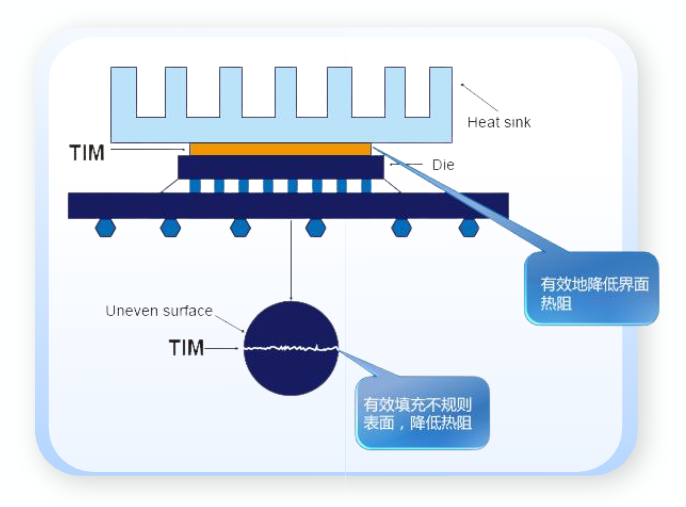

The surface of the IC and heatsink may appear flat. However, at the microscopic level, there are microscopic bumps and bumps on the surface, such as scratches generated during the manufacturing process. As a result, even if the IC and heatsink are in direct contact, there will be a small air gap between them. Since air is an excellent thermal insulator (low thermal conductivity), the heat generated by the IC is propagated in a way that avoids the air gap. As a result, the heat cannot be dissipated to the outside efficiently

TIM (Thermal Interface Material) is the solution to this problem because it will fill the air gap between two irregular surfaces, reduce thermal resistance, improve the heat dissipation performance of the device, and effectively release heat from the IC to the outside. It is currently recognized as a good thermal solution in the industry

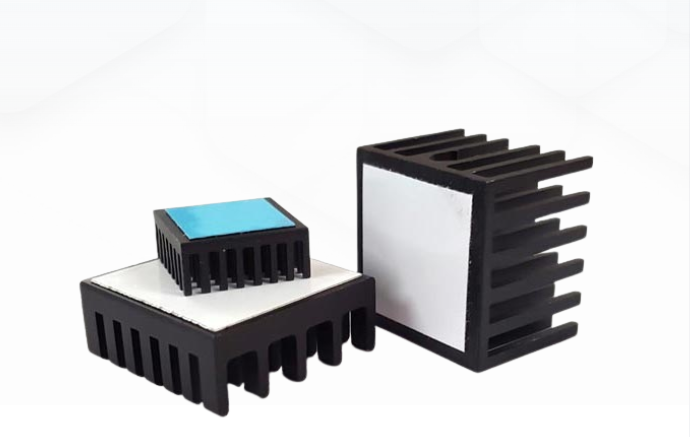

TCMP GP 35# High Performance Thermal Interface Composite

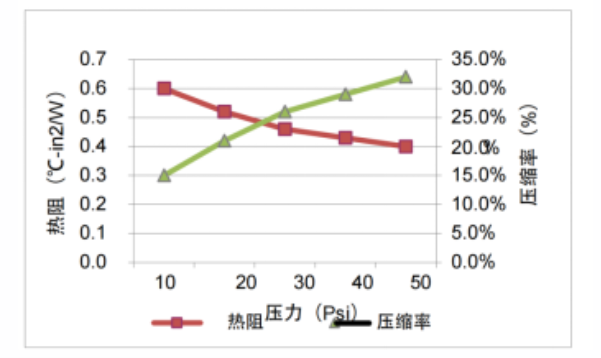

TCMP GP 35# is a high thermal conductivity material with a thermal conductivity of 3.5W/mk, which has good thermal conductivity, good surface wetting properties, and is ultra-soft, easy to operate and easy to die-cut, and can achieve low interfacial thermal resistance performance at relatively low pressure. It is applied to the power device and the heat dissipation aluminum sheet or machine shell, which can effectively remove the air and achieve a good filling effect

| Features | Typical | Standard |

| thickness | 0.3~7.0 | Visual |

| density (g/cm3) | 3.1 | ASTM D792 |

| hardness(Shore 00) | 50-70 | ASTM D2240 |

| Flammability rating | V-0 | UL 94 |

| Operating temperature(℃) | 40 to 150 | N/A |

| Volume resistivity(Ω.cm) | 4.2x1010 | ASTM D257 |

Product Features:

▶ Good gap filling capacity and low thermal resistance

▶ Thermal conductivity 3.5W/mk

▶ Soft and compressible

▶UL94 V-0 flammability rating

▶ Double-sided slightly viscous, easy to operate

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com