What is Optical Bonding?

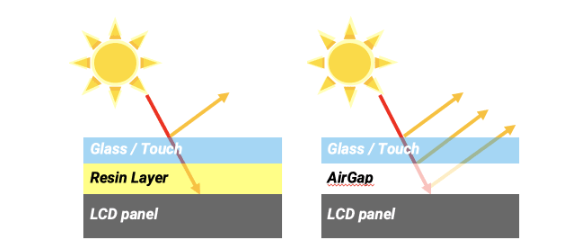

Optical bonding is a technique used to tightly connect transparent touchscreens, displays, or other optical components to the surfaces of materials such as glass and plastic. This technology is designed to improve the visual quality, durability, and readability of displays, especially outdoors or in high-light conditions.

In the optical bonding process, a transparent adhesive or glue is used to fill the void between the two surfaces, and even contact between the two surfaces is ensured by pressurization, heat, or UV curing. This contact eliminates air or liquid between surfaces, reducing reflections and refractions, improving the display's contrast, brightness, and readability. Optical bonding can also improve dust, water, and shock resistance, extending the life of the display.

Optical bonding technology is particularly useful in the following situations:

▶ Outdoor displays: In outdoor environments, the light is intense and prone to reflection and refraction. With optical bonding, these problems can be significantly reduced, making the display easier to read.

▶ Touchscreen: Using optical bonding on a touchscreen can improve touch accuracy, reduce reflections, and improve the user experience.

▶ Medical devices and industrial control panels: In applications that require high readability and durability, optical bonding can enhance the performance of the display so that it works well in a variety of environments.

▶ Aerospace and military applications: In applications that require a high degree of durability and reliability, optical bonding can provide better protection and protection

While optical bonding can significantly improve the performance of displays, it can also increase production costs and introduce manufacturing complexity. Different optical bonding technologies and materials can be selected based on specific application needs to balance performance, cost, and manufacturing requirements.

Optical bonding is popular in the medical, military, transportation, and retail sectors, where higher performance displays are required due to harsh environments. Optical bonding is suitable for industries that tend to use rugged displays in high-reliability environments or where displays need to be viewed in high ambient light conditions. When used outdoors or in high-light environments, the optical bonding process is particularly suitable and more effective

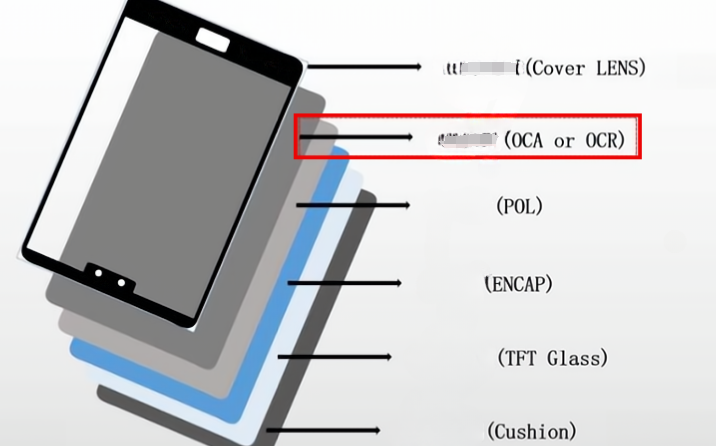

What is OCA/OCR bonding?

OCA bonding

(Dry bonding with transparent adhesive tape)

OCA bonding or optically clear adhesive bonding is an alternative form of bonding that is more suitable for higher production volumes. OCA bonding uses an optically clear adhesive film to bond touch screen or cover glass to the surface of the display. Although there are some mechanical limitations to OCA bonding, we offer a wide range of film thicknesses that can help overcome these challenges

OCR bonding

(Wet bonding with transparent resin)

OCR bonding, also known as optically clear resin bonding, is a technique used to bond two or more surfaces together. OCR bonding involves applying a thin layer of transparent silicone between the display and the cover glass or touchscreen. This process can be done manually or using automated equipment. OCR bonding is preferred in applications where the substrate is irregularly shaped or curved. In addition, OCR bonding can provide excellent optical clarity and minimize the appearance of visible gaps