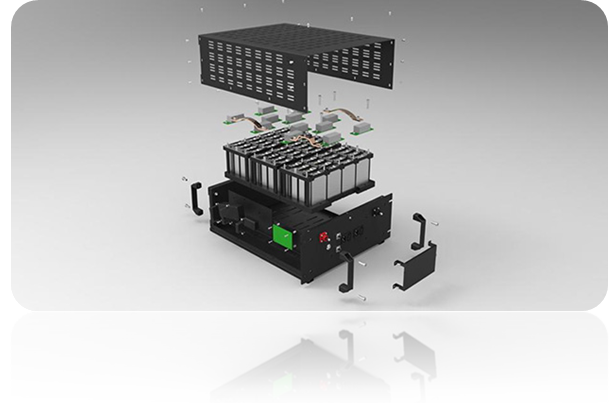

BMS plays an indispensable role in the detection and management of batteries in new energy vehicles and energy storage systems, and is an indispensable part of power and energy storage battery packs. Due to the long-term exposure to vibration and corrosive gas environments, the stability of data transmission and the real-time response of battery conditions have become the primary guarantee for system safety, and reliable connection in harsh environments has become a necessary condition for the safe and efficient operation of BMS. Therefore, the quality and technology of photovoltaic products must be recognized by the international market

Since 2012 years, Shanghai Beginor Material has accumulated rich experience in the development and application of new and traditional industries, and its product technology and quality are at the leading level in the same industry. It can provide a full range of product lines, sealants, potting castables, structural adhesives, three-proof coating adhesives, high-performance thermal interface materials and other products, which are widely used in new energy vehicles, green wind power industry, intelligent manufacturing industrialization, smart city remote monitoring, healthy life and other national pillar industries

Adhesive solutions for photovoltaic energy storage modules

Application

◆ Cell bonding

◆ BMS circuit board three-proof coating

◆ Pack shell bonding seal

◆ Thermal conduction and fixation at the bottom of the cell

Recommended Models: BEPU 5110 (Non-Thermally Conductive) / BEPU 5115 (Thermally Conductive) ▶ Two-component polyurethane structural adhesive ▶ 40 minutes of fast initial curing, shear strength > 10Mpa ▶ BEPU 5115 thermal conductivity: 1.5W/mK

|  |

Recommended Models: BECOAT 9062 ▶ Low VOC, low viscosity, with fluorescent indicator ▶ 100% solid content, operating temperature range -60 to 280°C

|  |

Recommended Models: BESIL 9336 (FIPG)/ BESIL8520 A/B (CIPG) ▶ Adhesive strength> 1.2Mpa ▶ Fast surface drying, good compatibility with addition molding compound ▶ BESIL8520 1:1 paste thixotropy, no adhesion can be repaired

|  |

Recommended Models: STCMP Gap filler ▶ 1:1, low stress, low hardness and micro-viscosity ▶ 3 hours of initial solidification at room temperature, elongation at break > 350% |  |