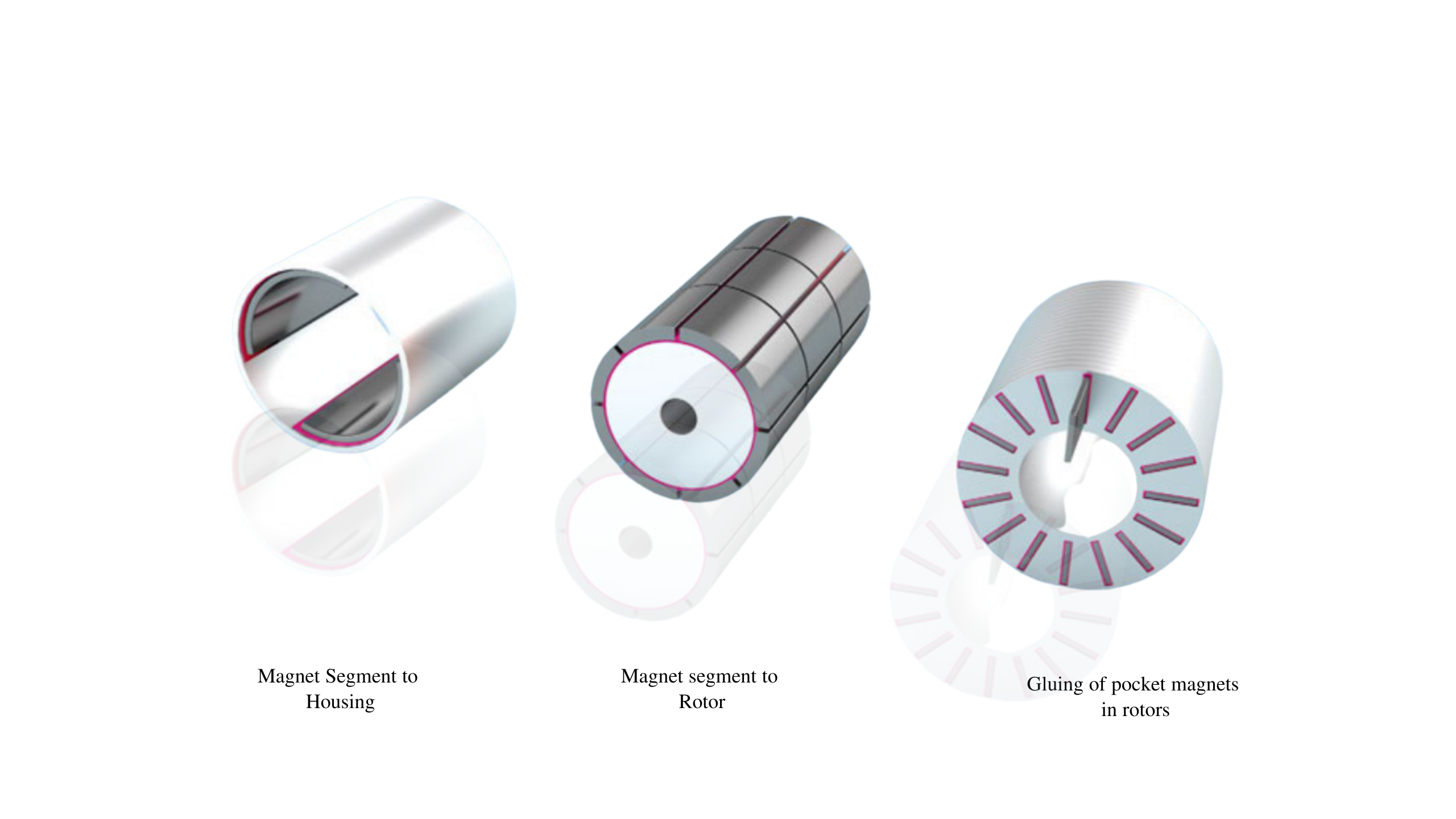

All electric motor manufacturers have a common goal: to make them smaller and more powerful while increasing efficiency. In the effort to achieve this, several aspects must be taken into account, such as the lamination design, in which the magnet is optimally embedded in the lamination stack and that the gap between the magnet and the coil and housing is as small as possible.

Bonding with adhesives has many advantages over these traditional methods, such as mechanical clamping or wrapping magnets. It is particularly suitable for the three steps of motor assembly: connecting the magnet and lamination, connecting the shaft and rotor, and connecting the stator and housing.

Why use adhesives?

The adhesive distributes stress across the entire bonding surface, reducing stress concentration points and reducing the risk of breakage. Due to the high vibration environment, any space between the components will generate vibrations and increase the noise and wear of the components. This is especially important for coating lines that can be delamiated by short circuits caused by vibrations. Adhesives minimize noise and vibration due to their viscoelastic properties. Adhesives bond to a variety of substrates, including metal and plastic materials, and produce strong bonds very quickly, making them ideal for large-scale manufacturing.

What are the challenges of adhesives?

Bond Strength and Durability Vibration: Magnets in motors need to withstand large forces and vibrations, so it is necessary to select an adhesive with sufficient strength and durability.

Thermal stability of the adhesive: During the working process of the motor, the magnetic material will be affected by high temperatures, and the adhesive also needs to have good thermal stability to ensure that the bond does not fail.

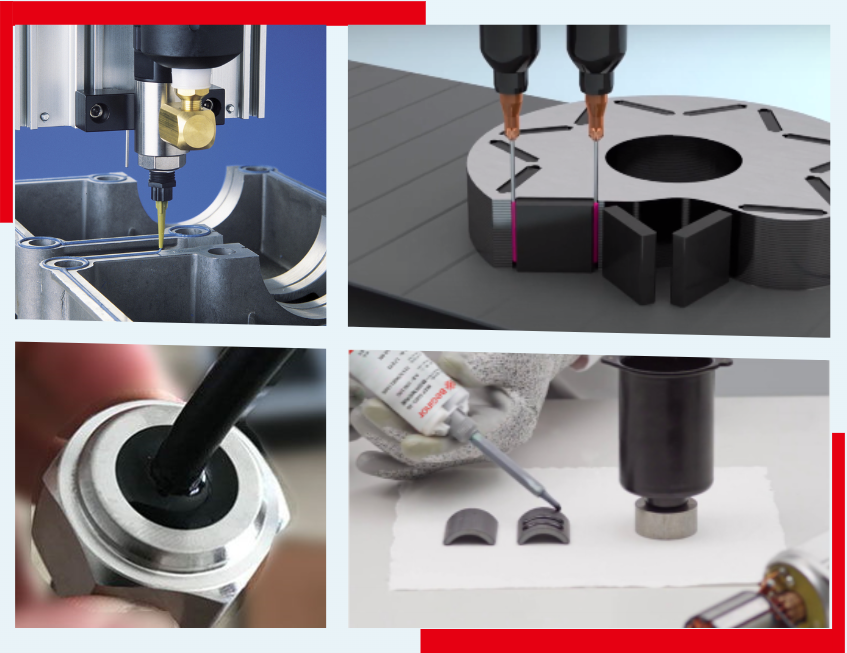

Flow of adhesives: Magnetic materials in motors often have complex shapes and sizes, requiring the use of adhesives to bond them together. Due to the irregular shape and size of magnetic materials, the flow of the adhesive needs to be good enough to ensure that the adhesive can adequately fill the voids and thus ensure the strength of the bond.

Different materials need to be bonded: different surface materials between the two bonding surfaces (different in shape and composition than common types of magnets, including neodymium, samarium cobalt, and ferrite/ceramic magnets. )

BEEP 621 New Epoxy Adhesive

BEEP 621 new is a black and solvent-free one-component epoxy structural adhesive with good toughness and impact strength, when it is fully cured by heat, it can provide excellent bonding, electrical, moisture resistance and mechanical properties, and has high bonding strength to most substrates including glass, metal, ceramic, etc., while meeting the bonding and mechanical properties requirements at high temperatures.

It is widely used in automotive electronics, pressure sensors, connecting wiring harnesses, and motor magnetic sheet bonding

Product Features:

◇ One-component paste micro-flow

◇ Thermosetting glue, high TG

◇ Good toughness and impact resistance

Product parameters

| density | 1.25-1.35 g/cm3 |

| viscosity | 278 rotor 93C, 0.5rpm, Pa·s |

| Long-term temperature range | –50-180 ℃ |

| hardness | 85±5 Shore-D, 25℃ |

| Volume resistivity | –50-180 Ω· cm, DC500 |

More product recommendations

BEEP 6211-146A/B Epoxy Adhesive ◇ Two-component 2:1 volume ratio mixing ◇ Can be cured at room temperature or heat ◇ Good peeling power | ◇ Two-component 2:1 volume ratio mixing ◇ Can be cured at room temperature or heat, high TG ◇ Good peeling force and high shear force | ◇ One-component semi-fluid ◇ Thermosetting glue, high TG ◇ Good adhesion |

Which TIMs is the best choice?

Basically, each application and production will be suitable with a different type of thermally conductive materials. To receive further consultant, please contact our Glue Expert at:

Hotline: (+86) 18121160382

Email: marketing@shbeginor.com